6 Mar 2023 | Non classé

Smart battery chargers are becoming increasingly popular for recharging the batteries of all electronic devices and electric vehicles. However, with the multitude of solutions on the market, it can be difficult to select an efficient charger that suits your needs.

In this article, we will detail the added value and advantages of the intelligent battery chargers developed by Selfenergy in order to assist you in your project.

How a smart battery charger works

First of all, what is a smart battery charger and how does it work?

Unlike a standard charger, the smart charger uses advanced control algorithms to optimise battery performance, safety and life.

This type of charger is therefore effective in two applications:

- Recharging the on-board battery from a mains socket in industrial applications, electric bicycles or electric vehicles, known as an AC/DC smart charger

- Recharging an auxiliary battery from a main battery: DC/DC intelligent charger-converter, the DC/DC converts a direct current (DC) into another direct current.

These two categories of smart chargers are different and have their own characteristics.

The special feature of smart chargers is their ability to communicate. The software they contain enables them to retrieve key information on the state of the battery, in particular its capacity, voltage and cell temperature, in order to adapt their operation accordingly.

Selfenergy takes advantage of each of the characteristics of smart chargers in order to develop innovative high-efficiency solutions adapted to each need.

The advantages of Selfenergy’s smart battery chargers

Optimising the life of the battery

The main factor in the ageing of a battery is the rise in temperature of the cells. This overheating can occur especially during charging.

Selfenergy’s intelligent battery chargers regulate the battery’s charge by communicating with its BMS (Battery Management System). The BMS is an electronic management board linked to the battery that monitors its operation by collecting important information such as the SOH (State Of Health), the SOC (State Of Charge) or the cell temperature.

By taking into account the information transmitted by the BMS, the intelligent charger adapts its charging current to the temperature of the cells and enables the battery to be charged efficiently. In the event of high temperatures, for example, it is able to adapt to respect the recommendations of the cells and thus optimise the life of the battery.

A standard battery charger has to make a compromise between :

- A slow but safe charge to optimise battery life

- A fast but aggressive charge for the cells and therefore with a strong impact on the life of the battery

The particularity of the intelligent chargers developed by Selfenergy lies in their ability to communicate directly with the battery via the BMS. Thanks to this communication, the chargers optimise the battery’s charging performance in real time by maximising the charging speed without degrading the battery.

Optimising battery safety

In order to optimise the safety of a battery, Selfenergy implements an additional charging phase in the development of its intelligent chargers: the “acceptance” phase.

This phase comes at the beginning of the battery charging process and complements the classic “Boost-Absorption-Floating” charging profiles and allows to start a very gentle charge and to make sure that the battery and the wiring are defect-free.

In addition, the charging voltage of Selfenergy’s intelligent battery chargers is fully adjustable according to the electrochemistry and characteristics of the battery. The set end-of-charge voltage can never be exceeded, thus avoiding any risk of overcharging the cells and therefore of thermal runaway.

Optimal efficiency for better energy conversion

Selfenergy’s smart battery chargers guarantee an efficiency of up to 97% without any active cooling system.

This high efficiency is the result of several factors working together to dissipate the maximum heat and limit losses during energy conversion. These include the use of the most advanced electronic components (drivers and MOS) on the market and an innovative chopping system.

At Selfenergy, we develop customised smart battery chargers adapted to all your technical needs (energy sources, space optimisation, power rating, etc.) whatever your industry.

Would you like to learn more about our smart chargers? Contact our experts.

17 Nov 2022 | Le saviez-vous

Electric current exists in two forms: alternating current (AC) and direct current (DC). In alternating current, which is used to transport electricity over long distances, electrons flow in both directions in the electrical circuit to limit energy losses. In direct current, which is found in batteries, the electrons flow in one direction only and more stably.

From these forms of current come two types of charger that can effectively recharge a battery: the AC/DC charger and the DC/DC charger or converter.

In this article you will find the specifics of the AC/DC charger and the DC/DC charger in order to understand the differences between them and to select the most suitable solution for your needs.

The AC/DC charger

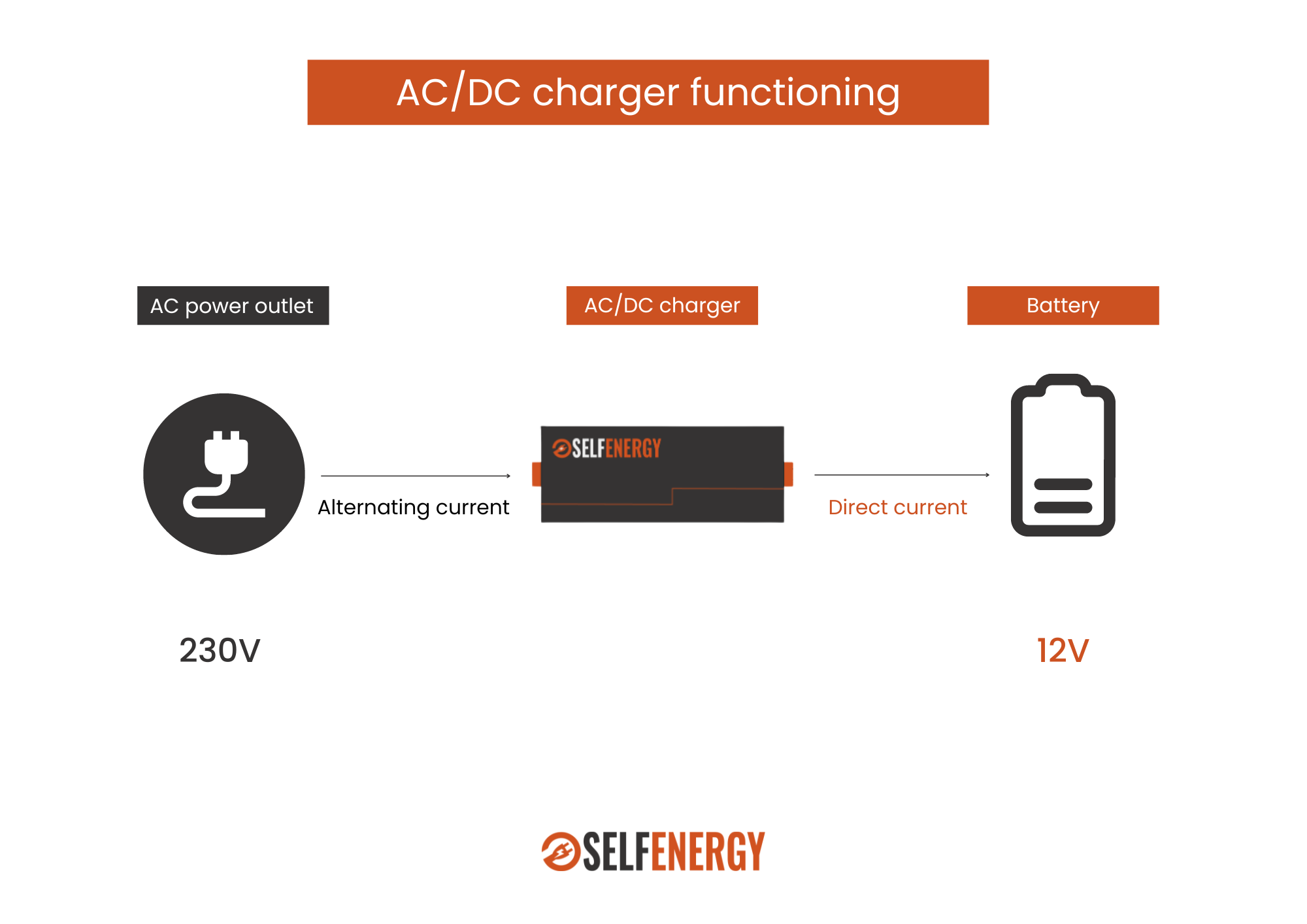

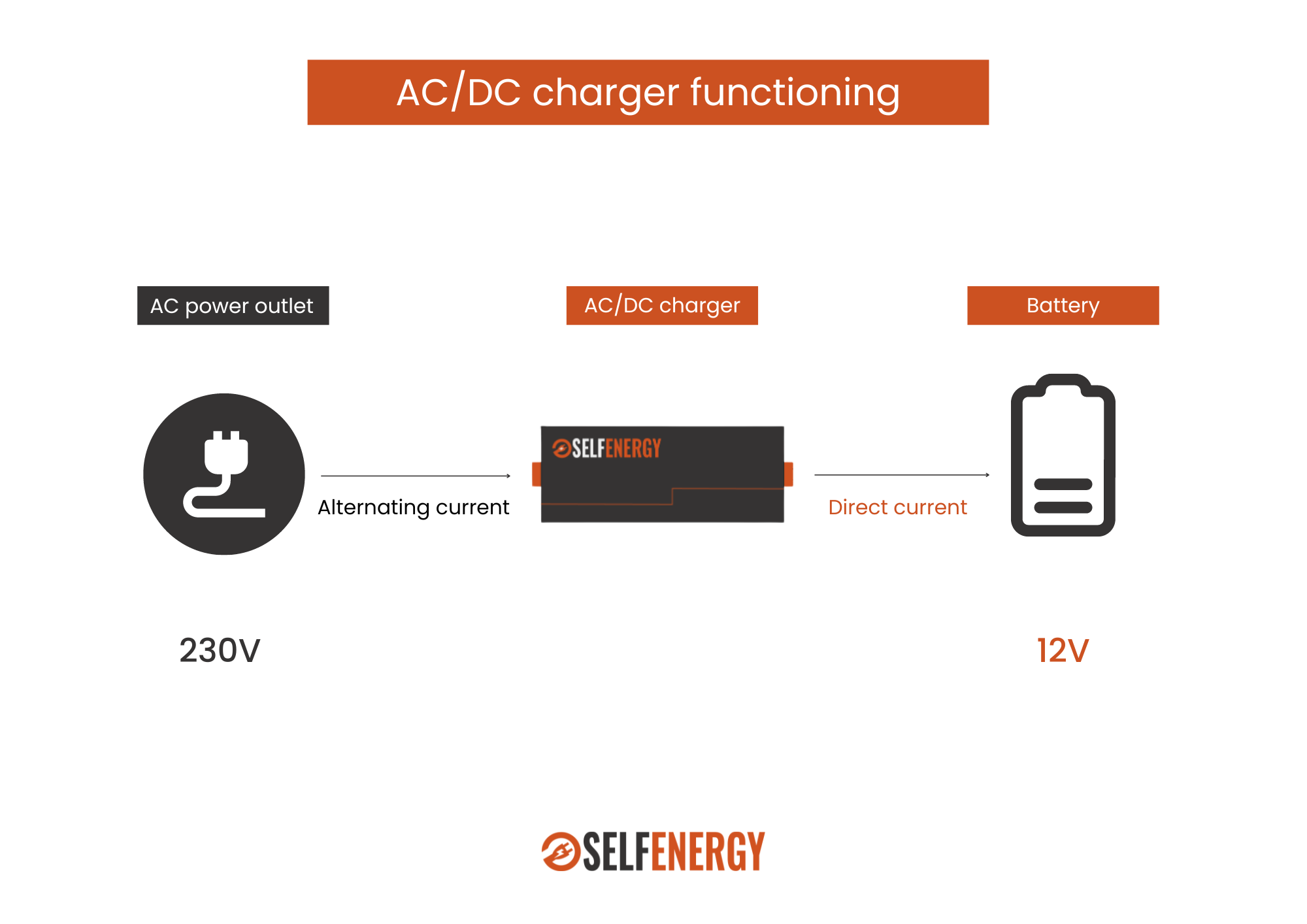

The AC/DC power supply applies to all kinds of electronic devices with or without a battery (television, mobile phone, electric bikes, etc.). It transforms the high voltage of the alternating current (230 V in France) into a voltage, generally lower, adapted to the supply of an electronic device or a battery.

AC/DC charger and battery charging

A battery cannot be recharged directly from AC current because of the incompatibility of its DC voltage and the AC voltage of the public electricity network. It is therefore essential to be able to convert the alternating current into direct current of the same voltage as the battery in order to recharge it. In other words, convert the current from AC to DC.

Applications and functioning

The AC/DC charger can be used to recharge all types of batteries, from the battery of an electric drill to that of an electric vehicle.

Thanks to the electronic intelligence it contains, it can convert an AC voltage from the public grid (230V) into a DC voltage from a 12V, 36V or 48V battery for example.

3 characteristics of the AC/DC charger

- Removable for certain applications (bicycles, electric vehicles, scooters, drills, robotics etc)

- Can be used in certain applications such as boats

- Converts alternating current to direct current

The DC/DC charger

DC/DC charger and battery charging

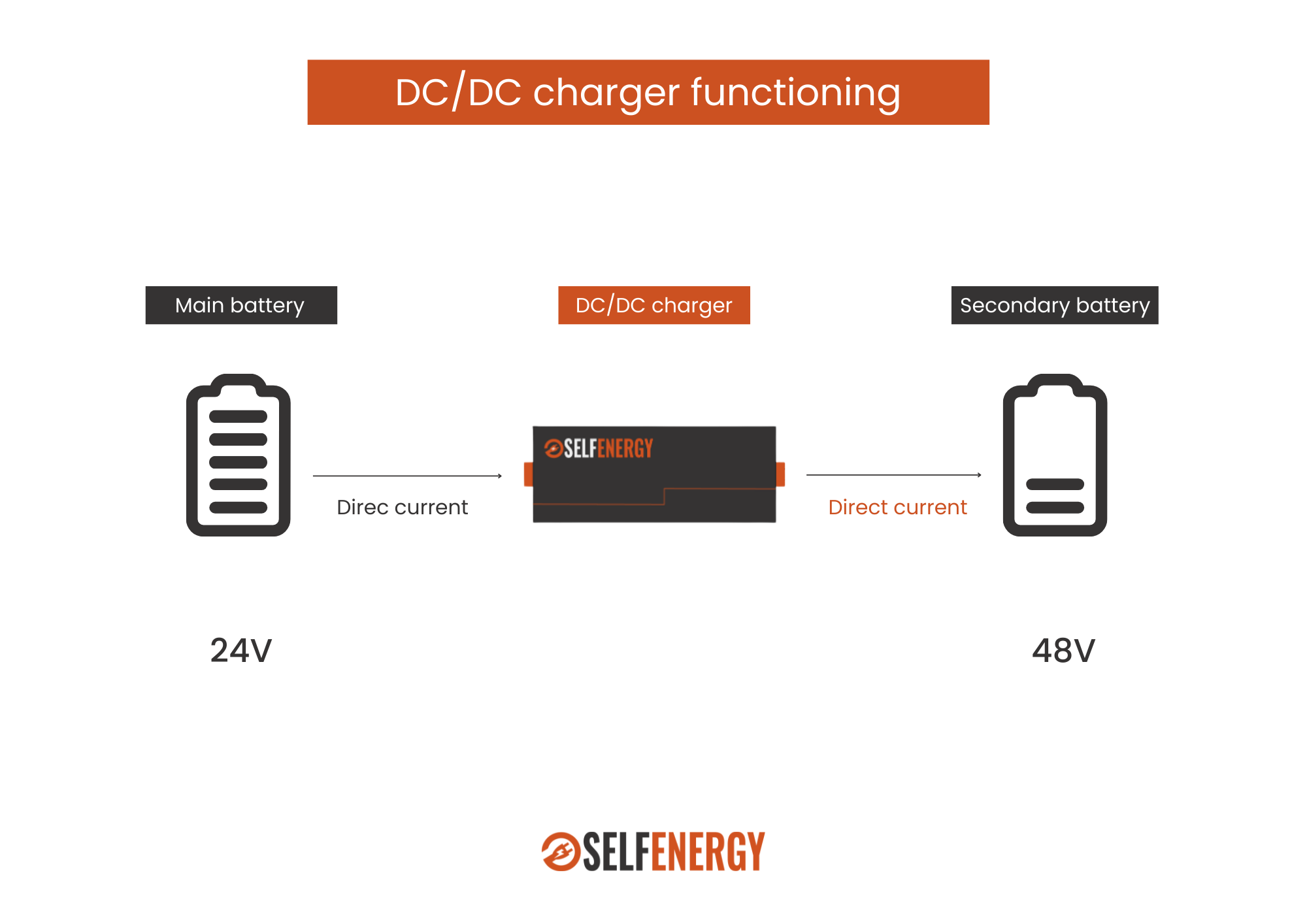

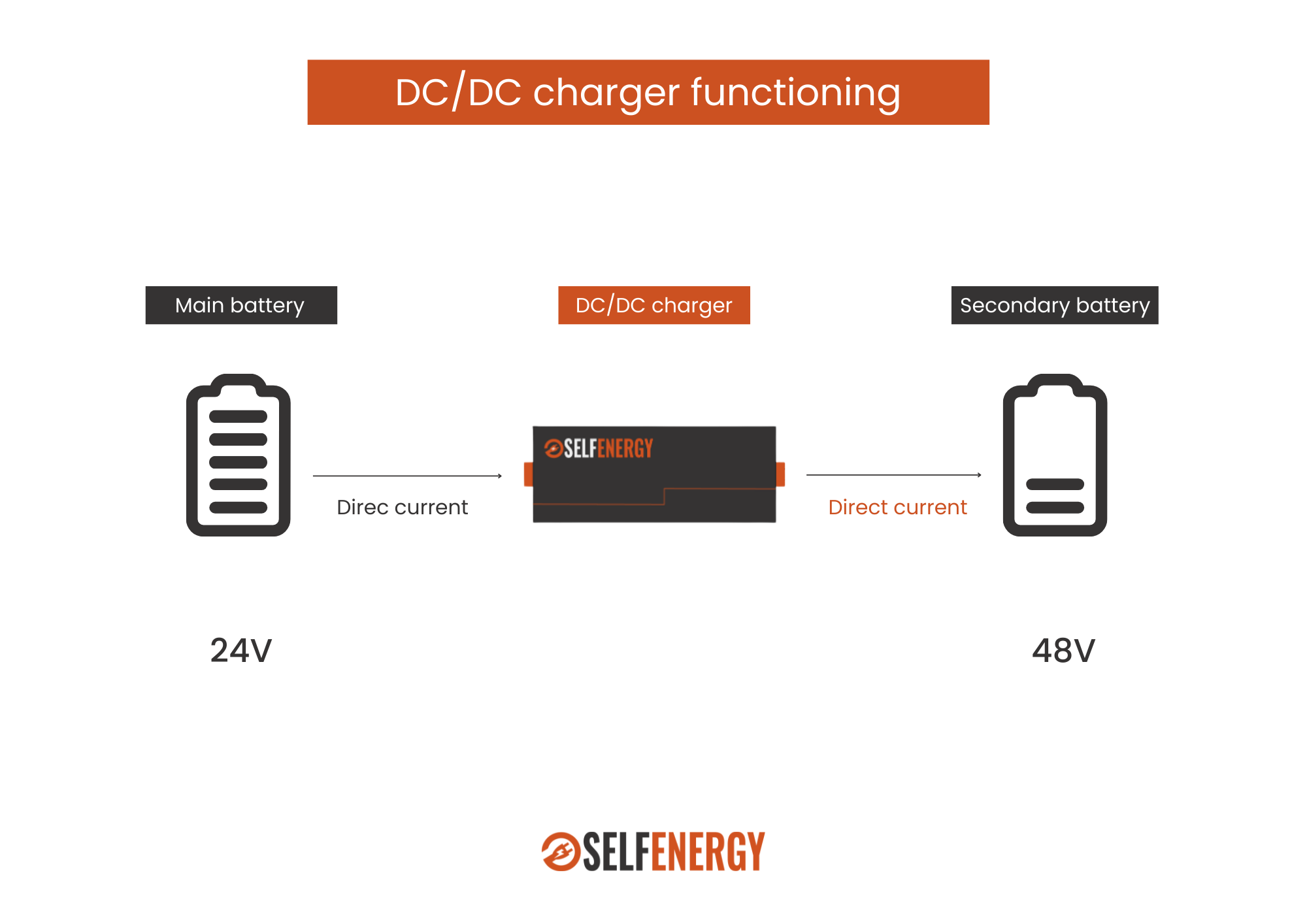

By definition, DC/DC charging is the conversion of direct current (DC) to direct current (DC). In this case, there is no need for an AC current because the energy is transformed on board the same application that already has a DC voltage.

The charger or DC/DC converter supplies an auxiliary battery running on DC from a motor battery, also running on DC.

Applications and functioning

The DC/DC charger or converter is most often used in boats, motor homes or professional vehicles (ambulances, foodtrucks, large utility vehicles, etc.) that have an engine battery and an auxiliary battery to operate the vehicle’s ancillary equipment (household appliances, lights, etc.).

The role of the DC/DC charger will be to recharge the auxiliary battery from the AC current of the engine battery. Thus converting the engine battery voltage into the auxiliary battery voltage.

3 features of the DC/DC charger

- On board a boat or motor home

- Continuously connected to the auxiliary battery and the engine battery

- Converts direct current into direct current

AC and DC converter: Why choose Selfenergy for the design of your charger

Expert in the design and industrialization of intelligent chargers, Selfenergy accompanies you in the customed development of your AC/DC or DC/DC charger.

- Selfenergy’s Converty AC (AC/DC chargers) can transform any AC current into DC current with a voltage of up to 48V or more depending on your project and application.

- Selfenergy’s Converty DC (DC/DC chargers) garantee intelligent and efficient charging of an auxiliary battery from 12V to 48V from the engine battery.

In order to optimise the performance of your battery, Selfenergy chargers adapt to all electrochemical technologies (lithium-ion, lead-acid, Ni-MH, etc.) with a charging power of up to 1000W output. They can be parallelized to deliver more power and are IP43 waterproof rated.

Want to know more about our chargers? Our sales team and engineers are at your disposal to help you in all stages of your project. Please contact us for more information.

17 Aug 2022 | Le saviez-vous

The DC/DC charger has a significant function in the energy conversion on board a campervan, a boat or a professional utility vehicle.

In addition to recharging the auxiliary battery, it has a real impact on its performance and lifetime, regardless of its electrochemistry.

How does a DC/DC charger work?

The main function of the DC/DC charger is to recharge an on-board auxiliary battery in a vehicle with ancillary electrical and electronic equipment with a power requirement. This charging is done from any DC source such as an engine battery.

To do this, it uses 3 charging phases to transfer energy into the battery:

- Bulk phase: The battery is charged at constant current (maximum charge current) until the end-of-charge voltage is reached;

- Absorption phase: The battery is charged at a constant voltage with a gradually decreasing current to reach the full charge. A low minimum current can allow the cells of lithium batteries to be properly balanced;

- Floating phase: To ensure good battery life, the full charge voltage should not be maintained. The floating phase allows the voltage to be kept high enough to keep the battery charged without degrading it.

Why choosing a DC/DC charger for a lead-acid auxiliary battery

The limits of the splitter coupler

As the name suggests, the splitter coupler separates the engine battery from the auxiliary battery. Thanks to this separation, it ensures that the auxiliary battery can be charged from the engine battery while preserving both.

When the engine battery is charging, i.e. when the motorhome or boat is running, the separator coupler connects the two elements.

When the engine is switched off, when the voltage of the engine battery drops, the separator-coupler cuts this link in order to preserve the engine battery.

This electronic solution is most often used for lead-acid auxiliary batteries, which are less complex and less expensive. However, the use of a DC/DC charger is recommended to ensure a better charge of the auxiliary battery and a longer life.

The advantage of a DC/DC charger for a lead-acid auxiliary battery

The DC/DC charger goes further than a simple splitter coupler. It offers the advantage of being a real battery charger compared to the splitter coupler. It ensures a safer and more optimal charging of the auxiliary battery thanks to the Bulk/Absorption/Floating charge profiles.

Why choosing a DC/DC charger for a lithium auxiliary battery

The last few years have seen important developments in the battery sector. Lead-acid batteries, which were not very powerful, have progressively given way to lithium batteries (NMC, LTO, LFP, etc.) which are more powerful and have a higher energy density and a longer life span.

A necessity for good charge cycle management

Whether it is for a motor home, a boat or a professional vehicle, manufacturers are now more inclined to use lithium auxiliary batteries in order to benefit from their many advantages.

However, while these batteries are more efficient, one of the reasons for their rapid wear and tear is poor management of their charge and discharge cycles. The use of a DC/DC charger is therefore essential to optimise their life span thanks to adapted charging profiles.

Selfenergy®‘s DC Converters are designed with customised charging curves that take the form of two additional steps to provide a complete and safe charge:

- The acceptance phase: Before starting a high current charge, the Selfenergy® charger checks the battery for defects. The battery is charged at low current to allow the charger to check that the battery reacts correctly to this slow charge;

- The maintenance phase: After several days or if the charge voltage decreases, the DC Converty automatically restarts a Bulk-Absorption charge cycle to ensure that the auxiliary battery remains fully charged.

Connectivity to optimise the performance of the lithium battery

With more modern electronics and algorithmic developments, DC/DC chargers are becoming increasingly efficient and can adapt to complex batteries such as lithium batteries to optimise their performance through connectivity.

Connectivity between DC/DC charger and battery: What is it?

Connectivity refers to the ability of a charger to interface with the battery through a communication protocol such as CAN Bus. Through this protocol, the charger’s electronic board communicates with all the elements of the system, including the battery’s Battery Management System (BMS).

The BMS is an electronic battery management board that manages and monitors all the elements that make up the battery in real time. Today, on-board chargers such as Selfenergy®’s Converty DC are able to retrieve important information about the battery, such as its state of charge (SOC) or state of health (SOH), through the CAN Bus communication protocol to ensure a complete and safe recharge of the battery.

Do you need chargers and energy converters for your batteries? Select our customisable 12V, 24V and 48V DC/DC chargers and converters as well as our customised offer.